Benefits

Compelling benefits over traditional stamping

Through automation and process innovation, Inno-Spin offers significant cost, process, quality control and environmental benefits while maintaining the dimensional and performance characteristics of stamped products.

The benefits

Cost Savings

Proven to dramatically lower unit costs by eliminating material waste from traditional stamping

Precision Dimensional Accuracy

Consistent dimensional accuracy verified across millions of parts

Secondary Processes

Enhance throughput and eliminate secondary processes, also resulting in cost savings

Innovative Production Process

Highly automated production process with 100% in-line testing possible

Reduced Carbon Footprint

Reduces scrap, emissions, handling and overall waste

Blanks

Flat and cylindrical blanks fit into existing forming operations

Quality Control Throughout

Tightly controlled production process

Lower Tooling Costs

Reduced startup costs and advantages across lot sizes

Rapid Prototyping

Rapid product development cuts time to market

Process Control

Tight control throughout forming process steps

Design Flexibility

Features which are not possible with traditional deep-draw or transfer presses can be incorporated in the Inno-Spin process

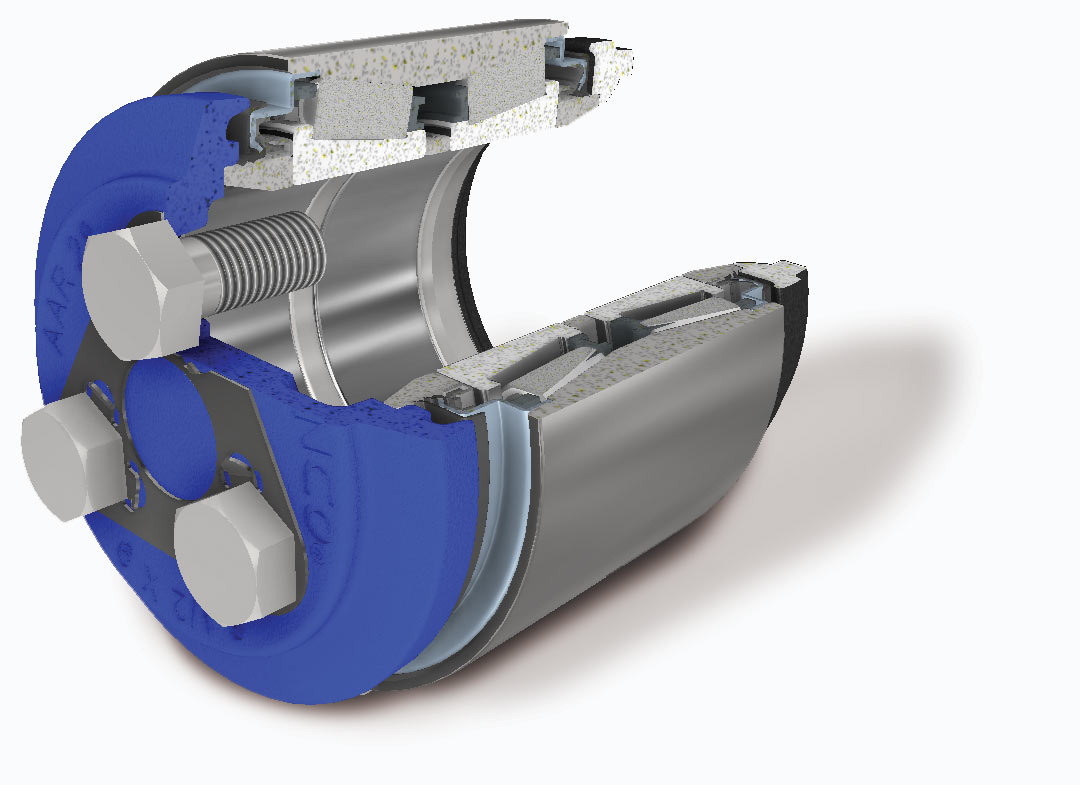

Side-by-side, there’s no comparison

Spin-form products from Inno-Spin have the flexibility to fit into existing operations (through blanking or semi-finished products) or completely replace transfer press operations. With less scrap, lower tooling cost, semi-automated changeovers, and enhanced quality control, Inno-Spin can achieve next-generation 3D printing at a fraction of the cost of traditional stamping.

|

|

|

PRODUCT TESTING:

Seal cases manufactured using Inno-Spin™ process pass rigorous testing standards

It’s time to rethink stamping. Talk to an Inno-Spin expert today.